Miroprint Silver 7

Miroprint Silver 7Item Code / Model Number:

Miroprint Silver 7

Miroprint Silver 7

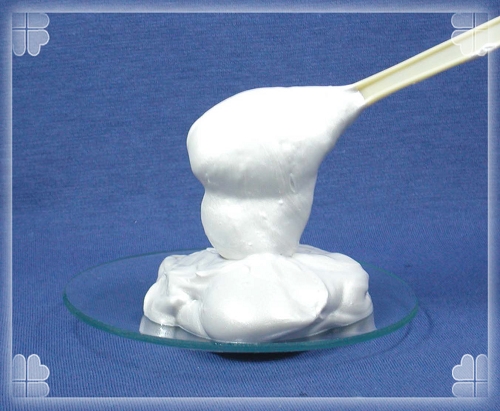

MIROPRINT SILVER 7 is a product ready for use for “pearl” prints, without metal particles. This characteristic makes it biodegradable in the purification systems.

MIROPRINT SILVER 7 differently from other resins, has a brightness degree equalling the normal printing pastes that contain metal microcapsules.

MIROPRINT SILVER 7 has been purposely designed for printing both alone and in association with acid dyes on silk and wool. Its film, highly flexible, also allows it to be used on Lycra and polyamide fabric for the manufacture of swimsuits.

MIROPRINT SILVER 7 can be printed both “dry-on-dry” (trolley and rolling tables) and “wet-on-wet” (manual and rotary machines), in this last case taking care that it is printed as the first colour.

MIROPRINT SILVER 7 does not dry up during the printing stage, does not clog up tumblers and frames (normal 14-thick or 55-thread tumblers for flat printing ).

MIROPRINT SILVER 7 does not damage the permanent adhesive film of printing mats, and can be easily removed with water.

MIROPRINT SILVER 7 given its high resistance to both oxidants and reductive agents, can be used for printing with acid dyes for corrosion and disperse dyes on acetate and polyester (in the last case, the following fabric-reductive washing does not imply lower strengths nor a change of tone in the product).

MIROPRINT SILVER 7 is only normally set by steaming at 102°C for 8 minutes or in the case of polyester, at 168 - 170°C. Being a self-catalyzed product, we suggest heat-setting for special cases only (e.g. printing on Lycra of “pearl” masses of a significant extent). For these cases, after the steaming and before washing the pieces, it is advisable to carry out a polymerization cycle for one minute at 130 - 140°C. In the case of articles which must not be steamed, a heat-setting cycle lasting two or three minutes at 150°C is enough (on this matter we wish to underline that the addition of 5 gr/kg of CATALIZZATORE EPF to the product allows the polymerization temperature to be reduced down to 100 - 110°C).

MIROPRINT SILVER 7 differently from other resins, has a brightness degree equalling the normal printing pastes that contain metal microcapsules.

MIROPRINT SILVER 7 has been purposely designed for printing both alone and in association with acid dyes on silk and wool. Its film, highly flexible, also allows it to be used on Lycra and polyamide fabric for the manufacture of swimsuits.

MIROPRINT SILVER 7 can be printed both “dry-on-dry” (trolley and rolling tables) and “wet-on-wet” (manual and rotary machines), in this last case taking care that it is printed as the first colour.

MIROPRINT SILVER 7 does not dry up during the printing stage, does not clog up tumblers and frames (normal 14-thick or 55-thread tumblers for flat printing ).

MIROPRINT SILVER 7 does not damage the permanent adhesive film of printing mats, and can be easily removed with water.

MIROPRINT SILVER 7 given its high resistance to both oxidants and reductive agents, can be used for printing with acid dyes for corrosion and disperse dyes on acetate and polyester (in the last case, the following fabric-reductive washing does not imply lower strengths nor a change of tone in the product).

MIROPRINT SILVER 7 is only normally set by steaming at 102°C for 8 minutes or in the case of polyester, at 168 - 170°C. Being a self-catalyzed product, we suggest heat-setting for special cases only (e.g. printing on Lycra of “pearl” masses of a significant extent). For these cases, after the steaming and before washing the pieces, it is advisable to carry out a polymerization cycle for one minute at 130 - 140°C. In the case of articles which must not be steamed, a heat-setting cycle lasting two or three minutes at 150°C is enough (on this matter we wish to underline that the addition of 5 gr/kg of CATALIZZATORE EPF to the product allows the polymerization temperature to be reduced down to 100 - 110°C).

- Keywords:

- pearl, effect, pringting paste